History and Culture of Leather

Discovery of Leather Tanning

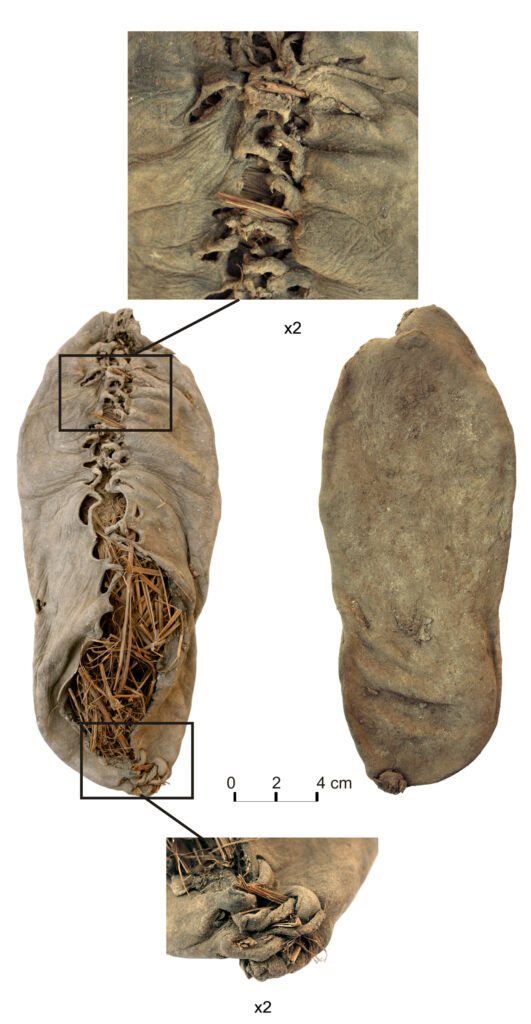

Leather tanning, a pivotal milestone in human history, likely began between 10,000 and 4,000 BCE. During the Upper Paleolithic (40,000–10,000 BCE), hides were used for protection against weather, possibly preserved with smoke or salt, though these methods were temporary. By the Neolithic period (9,500–5,500 BCE), people used animal marrow, brains, fat, and smoke to create more durable hides for clothing, shoes, tents, and tools, maximizing every part of hunted animals. True tanning, using tannins, emerged around 6,000 BCE in regions like Egypt, Mesopotamia, and China. The Egyptians, Babylonians, and Persians refined techniques, employing vegetable, oil, and mineral tanning with local materials like plant extracts, urine, and galls. Despite leather’s value, tanners were socially marginalized due to the unpleasant nature of their work, often relegated to city outskirts. Leather’s high cost and labor-intensive production (taking 9 months to 2 years) fostered sustainability, with every animal part repurposed and items repaired extensively.

The tanning process as we know it today, i.e., the preservation of the skin through the use of tannins, originated around 6,000 BCE in areas such as Egypt, China, and Mesopotamia. The people who lived in these areas, such as the Sumerians, already appreciated the tanning effects of aldehydes, essential oils, and galls at an early stage. Perfection of leather tanning techniques, however, was achieved by the Babylonians, the Egyptians, and the Persians. The Egyptians, for example, mastered oil-based tanning as well as mineral and vegetable tanning techniques. These techniques would not have been discovered if leather’s unique combination of qualities had not been recognized. Firstly, the different qualities of the available tannins in the direct living environment of the tanners had to be determined; no doubt people started experimenting with locally available ingredients originating from plants and trees, but also with waste products such as urine and pigeon droppings.

The development i.e. History and Culture of Leather and leather products kept pace with the great appreciation for materials and craftsmanship. The latter was in stark contrast to the work performed by tanners. In most societies, the tanning profession was seen as inferior, and as such, the tanner belonged to the lower layers of society. Working with dead animals, the smell of decomposition, and the risk of contamination with deadly bacteria were the basis for this. In India, tanners belonged to the group of casteless or untouchables: even walking in their footsteps was said to cause disaster. Tanneries were always located on the outskirts of a city to limit odor nuisance. After the leather had been tanned, the leather worker or shoemaker could get to work. Depending on their skills, their work was better appreciated, but rarely well paid. The group of wealthy people who could afford luxury goods was relatively small, and everyday utensils were therefore not quickly replaced but endlessly repaired.

Once we studied History and Culture of leather cost of materials encouraged sustainability . A purpose of use was devised for each part of the animal. Meat, fat, organs, blood, and marrow were used for consumption. Hair was used for making brushes or as a filling for furniture and saddles. Bones could serve as raw material for glue, tools, or be made into ornaments or even a sledge. Clothing and shoes were repaired for as long as possible before finally being replaced. Shoes, worn beyond repair, were cut up and reused for the repair of other shoes. Discarded utensils were first stripped of usable parts or finally used as firewood. One of the reasons materials used to be so precious was that it took a lot of effort to acquire them. Materials were made and/or processed manually, therefore the supply remained smaller than the demand. Exotic raw materials, such as tropical woods, silks, and spices, had to come from afar, and trade trips took a long time and were not without risks. Long processing times also applied to leather tanning. Depending on the thickness of the skin and the purpose of use, the tanning process took at least nine months. The tanning of sole leather, for instance, took one and a half to two years.

Historical References for the Use of Leather

Until the end of the nineteenth century, most leather was tanned with vegetable tannins. With the increasing knowledge about tannins and tanning processes, a greater variety of end products emerged over the centuries: thin, supple leather for the uppers of shoes; thick, water-repellent sole leather; sturdy leather for belts, bags, and knife holders; heavy, extra-thick leather for shields, breastplates, cuirasses, upholstery, and even bottles for the storage of oils and spirits. The list of applications turned out to be virtually inexhaustible. In fact, one could even say that leather was the most versatile material before it was supplanted by plastics in the twentieth century.

By combining the different types of leather, the number of applications multiplied, enabling the properties of the leather to be optimally utilized. For example, it enabled the Romans to produce shoes made from one piece of sturdy leather (the carbatinae) as well as openwork boots (the caligae), whose upper was made of supple leather and whose outsole was made of specially tanned bovine or ox leather. This is more or less how shoes are still made two thousand years later.

Intriguing Leather Processing Techniques

Until the invention of synthetic glues, leather products were made by sewing the different parts together. The objects were embellished with paint, engraving, embroidery, or decorated with (precious) metals. It is beyond the scope of this chapter to discuss all these techniques here. Nevertheless, there are two special techniques, mainly because they have been rediscovered recently by a number of contemporary designers.

-

Cuir Bouilli and Wet Molding

A very interesting application of leather is known by the name cuir bouilli. Cuir bouilli is an old Norman term for a technique that processes wet leather using a mold. It was used for the manufacture of drinking vessels, bottles, boots, helmets, cuirasses, and shields, among other things. Cuir bouilli literally means “cooked leather.” For centuries, that term has caused a lot of confusion as leather loses its firmness completely when heated to around 75–90°C and, after drying, becomes dry and brittle. So, in fact, the leather is not boiled but heated in hot water until the shrinkage temperature of the leather is reached. This limits the leather’s loss of elasticity and creates a stiff, strong material that can be used to manufacture both water-resistant and protective objects like containers and buckets. To maintain its shape, the leather still needs to be finished. A disadvantage of cuir bouilli is that it eventually may dry out and become brittle. A technique that leads to a more stable result is known as wet-formed leather. The leather is soaked in water for a few days and then pulled over a mold and dried. Optionally, separately manufactured parts are sewn together, as is the case with miners’ helmets. Wet-molded or formed leather is very strong and stable.

Case for a book, with fittings for a carrying-cord, 15th century. The coat of arms (on the other side) suggests it was made for a bishop. -

Gilt Leather

Another product in which moisture and temperature played a major role during production was gilt leather. Gilt leather was used as a wall covering and replaced the woven tapestries that had insulated the walls of palaces and castles for centuries. Gilt leather was produced in Ghadames, Libya, as early as the ninth century. Via the Umayyad conquest of Hispania, the technique also reached the Iberian Peninsula, from where it spread to Italy and northern European countries such as the Netherlands and England. Manufacturing gilt leather was a very time-consuming and specialist type of work that also required a great deal of material knowledge. Gilt leather was made by covering wooden frames with bovine leather. After stretching, the leather was covered with silver leaf. This could only be done in dry weather, as silver corrodes immediately and turns black in a damp environment. Subsequently, the silver leaf was covered with a yellow varnish, creating a golden shine, after which gilt leather is named. Once the varnish had dried, the leather could be embossed by pressing a pattern into the leather using moisture at a mild temperature. The gilt leather then would be finished by painting the front of the panel and by varnishing it again. After all these time-consuming steps, the gilt leather could finally be used to produce wall coverings, upholstery, folding screens, luxury boxes, or writing tables. Gilt leather remained popular as a wall covering well into the eighteenth century, after which it was replaced by wallpaper. The material also fell into oblivion for luxury items; only a few craftsmen would venture into the time-consuming process. Fortunately, leather has recently been revisited as a wall covering and even a floor covering. This time, however, in its natural splendor. The Shoe Museum has a very interesting collection of gilt leather fragments from the early sixteenth century to the early twentieth century.

Contemporary Use of Leather

The Industrial Revolution marked a turning point in the production of leather and thus also in the production of leather goods. The invention of the tanning drum accelerated the tanning process from a few years to a few dozen hours. It meant that leather became cheaper and accessible to a much larger group of buyers. The luxurious image remained, partly due to the arrival of chrome tanning, which infinitely increased the number of finishing options. Nevertheless, over the next century, leather increasingly lost ground to synthetic materials that were new and therefore fashionable.

In addition, the image of leather was damaged by the environmental impact of large-scale tanning—long before the discussion about the environmental impact of plastics. Despite the negative connotation that leather evokes in some, it is still a widely used material in several industries, of which the shoe and luxury leather goods industries are probably the best known. At least as important is the application of leather in the automotive industry and for interior design. These industries take full advantage of the unrivaled properties of this natural material.

-

Automotive

In the automotive industry, leather is mainly used for upholstery. Car upholstery must meet a large number of requirements. For example, it is important that the surface of the leather does not feel too hot or too cold for the car user. It also has to be durable, breathable, and it should not melt in case of fire. Many luxury car manufacturers still opt for leather, which meets all these requirements while having a luxurious appearance.

-

Interior Design

When talking about the use of leather in interior design, the first things that probably come to mind are leather rugs, table runners, wall hangings, cushions, upholstered sofas, and chairs. However, those who remember the gilt leather mentioned earlier in this blog will not be surprised to learn that leather offers many more possibilities in interior design. As in the heyday of gilt leather, contemporary smooth or hair-on leather tiles are a luxury option for cladding walls, doors, and fireplaces. Absolutely new is the application of leather on floors and stairs.

Historical Value and Connotations as a Design Resource

There is hardly any material that is currently still used that has such a long and diverse history as leather. With regard to sustainable development, Hideorzo design teams are advised to regard this as a design asset that can increase emotional attachment and willingness to care for a product.

While some current trends seem to focus on high-tech material finishes that create homogeneous and unchanging surfaces, embracing the natural characteristics and the aging patina of this material might refer to its historical usage and its durability across time. Hideorzo design teams accept the challenge to make use of leather in contemporary design concepts that fit the needs and demands of consumers and markets.

Get exclusive updates on the collection's launch, personalized communication and the House's latest news.

Get exclusive updates on the collection's launch, personalized communication and the House's latest news.